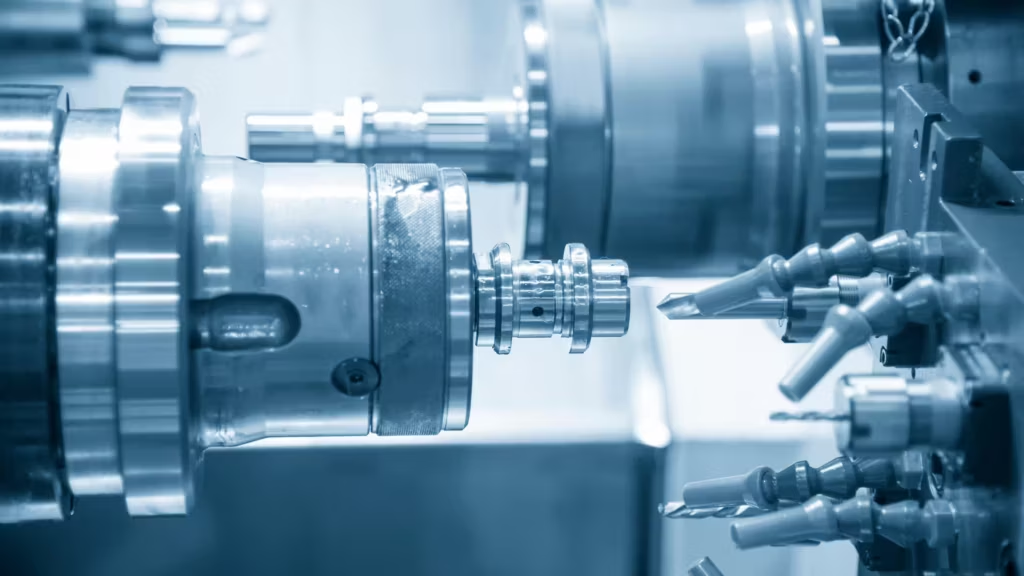

S&S Manufacturing is a leading provider of Multi-Axis CNC Turning services. Our state-of-the-art technology and skilled machinists enable us to produce precision parts with tight tolerances and high-quality finishes.

Process & Capabilities

Multi-Axis CNC turning employs computer-controlled cutting tools to shape rotating workpieces. We utilize advanced CNC lathes to create parts with a diverse range of geometries, including shafts, cylinders, and disks. Our services include:

- Lathe turning: This process allows us to create precise rotational parts such as shafts, cylinders, and disks.

- Live tooling turning: This advanced process allows us to create parts with additional features such as holes and slots.

- Multi-tasking turning: This advanced process allows us to perform multiple operations on the same machine such as milling, drilling, tapping, and knurling.

We can work with a variety of materials, including:

- Aluminum

- Stainless steel

- Titanium

- Plastics

- And more

Quality & Precision

By using cutting-edge CAM and CAD software, our specialized team of machinists and engineers ensures that every part meets or exceeds your expectations. We are committed to delivering high-quality pieces tailored to your specific requirements.

We prioritize prompt delivery and excellent customer service by establishing realistic production schedules that meet our clients’ needs. Our commitment to quality is backed by a satisfaction guarantee.

If you’re looking for high-quality Multi-Axis CNC turning services, look no further than S&S Manufacturing. Contact us today to learn how we can support your next project.